Laser Cutting: The Info You’re Lacking

Being able to meet the requirements of your clients is extremely important if you want to run a successful business, and this is possible only if you keep pace with the latest trends. Laser cutting technology with its new and improved features is able to keep up with the demands for increased speed while still providing you with high-quality products.

According to laser cutting Australia experts, the demand for laser cutting is constantly growing as it is one of the most safe and excellent ways of cutting materials without subjecting them to high temperatures. If your business requires cutting materials such as aluminum or plastic, partner with a reputable shop that offers laser cutting Australia wide and guarantees to cut raw materials without damaging the molecular structure.

The Basics Of Laser Cutting Technology

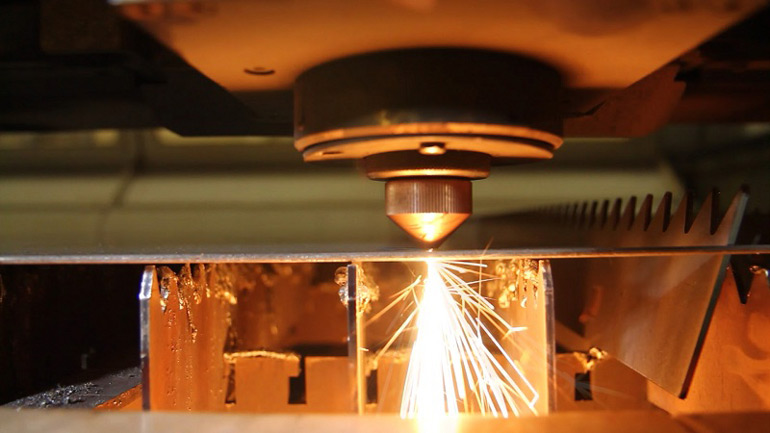

The secret of the popular laser cutting technique is that it uses a high-powered beam to cut specific materials according to computer-controlled parameters. The exceptional work provided by laser cutting consists of careful guidance of the beams along the material. Anything touched by these beams gets burnt, vaporized and melted. The greatest benefit of laser cutting is that the final product rarely needs additional work done as this process ensures an exceptional quality surface finish.

According to laser cutting Australia experts, there are two formats of laser cutting: gantry and galvanometer. Gantry systems are slow and they position the laser perpendicular to the material, so the machine physically directs the beam over it. They are commonly used for producing prototypes.

On the other hand, galvanometers use mirrored angles to position the laser beam and can cut up to 30 meters per minute. They are commonly used for full-on production work.

Basic Mechanics Of Laser Cutting Technology

Laser machines use special stimulation and amplification techniques to convert electrical energy into a high-density light beam. The stimulation occurs when electrons are provoked by an electrical arc or flash lamp, while the amplification happens inside the optical resonator that is set between two mirrors where one of them is reflective and the other one is transmissive.

Laser Light Properties

The word laser has become a household word, but few us now the true meaning of it. It is an acronym for: Light, Amplification, Stimulation, Emission, Radiation. Laser light has a number of unique properties. It is a monochromatic, directional, diffract and coherent.

Monochromatic – The emitted light from the laser is monochromatic, which means it measures the width of the spectral line. If the level of monochromaticity is high, the level of emitted frequencies by the laser are low.

Diffract – Diffraction refers to the process by which the laser light bends around sharp-edged surfaces.

Coherent – This refers to the relationship between electronic and magnetic components of the electromagnetic wave. The light from a laser is coherent when the laser’s wave lights are in phase and time.

The great thing about laser cutting technology is that most of the work is done through a computer, which reduces some of the operator’s work. Laser cutting setup is pretty simple, The newer equipment can automatically correct any important drawing exchange format (DXF) or .dwg (drawing) files to the desired results.